What is Boiler Maintenance: Industry's Approach with the Pressure Converter Tool

Boiler maintenance is critical in many industries, such as healthcare, hospitality, and manufacturing. Boilers are crucial equipment that needs proper maintenance. If organizations fail to maintain boilers properly, they can suffer catastrophic damages.

Industries like healthcare, hotels, or manufacturing use boilers to produce steam. This steam is used for sterilization, cooking, laundry, power generation, and many other purposes. Therefore, maintaining a standard pressure level is crucial in boiler maintenance.

Key Takeaways

- Understand what a boiler is, common types, and the key components of maintenance.

- Learn the role of a Pressure Converter Tool in boiler maintenance.

- Learn the industry’s approach for boiler maintenance including the types and strategies.

Understanding Boiler Maintenance

What is a Boiler?

A boiler is an important tool in organizations, especially in healthcare, hotel, and manufacturing facilities. It is a closed vessel that generates steam or hot water. This steam is used for many industrial purposes.

Industries use several types of boilers. According to their specific needs and the space available, they choose the right type of boiler from the following:

01) Fire-tube Boilers:

- This type is commonly used in smaller to medium-scale industries for heating and low-pressure steam.

- Heat passes through tubes surrounded by water.

02) Water-Tube Boilers:

- This type is ideal for high-pressure and large-scale operations. For example, power plants and chemical manufacturing.

- Water circulates inside the tubes and is heated by combustion gases outside the tubes.

03) Waste Heat Recovery Boilers:

- They basically take and reuse heat from industrial processes such as exhaust gases.

- These are common in cement, steel, and glass industries.

04) Packaged Boilers:

- These are pre-assembled units with compact designs. They are mostly used in medium-scale industries.

- Easy to install and operate.

05) Fluidized Bed Boilers:

- An efficient boiler type that burns low-grade fuels such as coal, biomass, or waste.

- Most commonly used in industries like paper, chemicals, and power generation.

These are some common types of boilers used by industries based on their needs. However, the steam produced by boilers fulfills many purposes relevant to different industry types. In healthcare buildings, it is valuable for sterile functions and laundry purposes.

In the hotel sector, it is used for cooking and laundry needs. In manufacturing firms, the steam or heat generated by boilers is useful to generate power or other industrial processes.

Important Components of Boiler Maintenance

Boiler maintenance involves several vital components that ensure proper boiler functioning. It helps reduce safety-related issues and unnecessary breakdowns. Let’s see some important components of boiler maintenance:

- Inspection: Inspection helps find any unwanted signs of corrosion, leaks, or other issues. Plus, inspection is important to ensure the proper functioning of boiler equipment. Inspection is done on the boiler components like safety valves, pressure gauges, controls, and other critical parts.

- Cleaning: Often or regular cleaning is crucial which helps remove accumulated sediment and debris from the boiler equipment and its components. This is important to prevent corrosion and improve boiler efficiency. Maintenance staff should consider cleaning the internal surfaces, tubes, and heat exchangers to maintain optimal heat transfer.

- Water Treatment: Water treatment is very important which prevents contamination in the boiler. A softener is a good option to treat water before loading it onto the vessel. Another crucial thing is to monitor the pH and alkalinity parameters to make sure that the water quality meets specifications.

- Maintenance of Controls and Safety Devices: It is necessary to maintain all control systems, safety devices, and alarms to make sure that they operate as per expectations. Further, replacing or repairing the malfunctioning controls, valves, and safety devices is vital to maintaining safe and efficient boiler operation.

- Efficiency Optimization: The engineers should be concerned about the crucial combustion settings, air-to-fuel ratios, and other vital parameters to optimize boiler efficiency which helps reduce fuel consumption. Additionally, installing energy-saving equipment such as economizers or heat recovery systems can effectively help with energy optimization.

- Training and Education: Organizations should offer necessary training programs to boiler operators and maintenance personnel. This will ensure that they understand proper operating procedures, safety protocols, and maintenance practices.

- Record Keeping: Keeping a record of maintenance activities, inspection reports, conducted repairs, and equipment histories is vital to track boiler performance and regulatory compliance. It is also important to analyze the maintenance records to identify trends, anticipate potential issues, and improve maintenance strategies over time.

The Role of a Pressure Converter Tool in Boiler Maintenance

What is a Pressure Converter Tool

A pressure converter is an online tool that effectively converts between different pressure units. Smart Tools AI offers an accurate and quick online pressure converter tool that helps streamline your work related to boiler maintenance and other related practices.

The tool supports multiple pressure measurement units like Newton/sq. meter (N/m²), Bar (bar), Decibar, Millibar (mbar), Centimeter Mercury, Centimeter water, Kilopascal (kPa), Megapascal, Pound-force/square inch (psi), Atmosphere (Normal) (atm), Atmosphere (Technical) (at), Millimeter mercury (mmHg), Torr (mmHg, 0°C) and many more.

How Pressure Converter Tool Helps for Boiler Maintenance

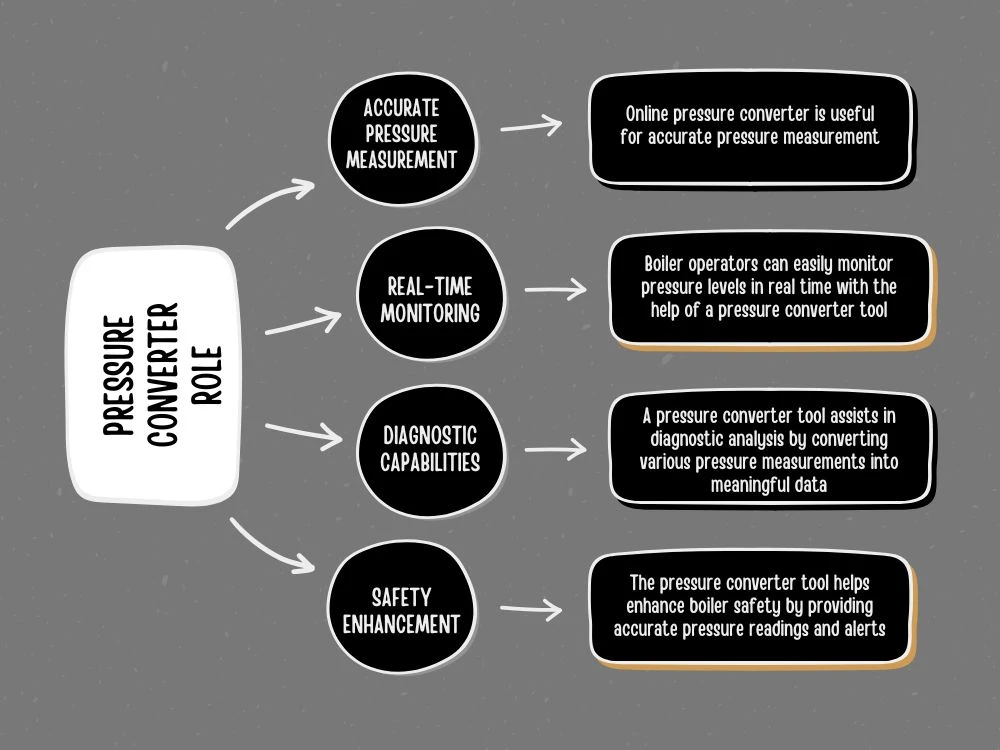

The pressure converter tool helps perform boiler maintenance by offering significant benefits to maintenance personnel and operators. Here are some benefits:

01) Accurate Pressure Measurement:

In organizations, accurate pressure measurement is crucial to conduct boiler maintenance. The online pressure converter tool is useful in this case which helps obtain accurate pressure measurements in various units.

This accuracy is salient to make sure that pressure readings are consistent and reliable. This way it facilitates effective monitoring of boiler performance.

02) Real-time Monitoring:

Boiler operators can easily monitor pressure levels in real-time with the help of a pressure converter tool. This will enable them to quickly identify any deviations from normal operating conditions.

Real-time monitoring of pressure levels is vital to act immediately in the circumstances of pressure fluctuations. This is helpful to prevent any kind of potential damage to boiler equipment which ensures continuous operation.

03) Diagnostic Capabilities:

A pressure converter tool assists in diagnostic analysis by converting various pressure measurements into meaningful data. This data can be analyzed to effectively diagnose boiler problems.

Also, by analyzing pressure trends and patterns, maintenance staff can easily identify potential issues as early as possible. This is crucial to take important proactive measures to address them before they escalate.

04) Safety Enhancement:

Safety is very important in boiler systems. This is crucial in abnormal conditions like serious pressure fluctuations. Maintenance staff can easily find pressure anomalies quickly by using the pressure converter tool.

This is crucial to take corrective action immediately. This way, the organization can prevent risks like accidents, equipment damage, and other potential safety hazards.

05) Integration with Control Systems:

Organizations can integrate the pressure converter tool with boiler control systems which will help automate the pressure monitoring and control processes.

This integration with control systems can streamline the maintenance workflows and enhance overall boiler efficiency by ensuring consistent and accurate pressure management.

Industry's Approach to Boiler Maintenance

Types of Boiler Maintenance

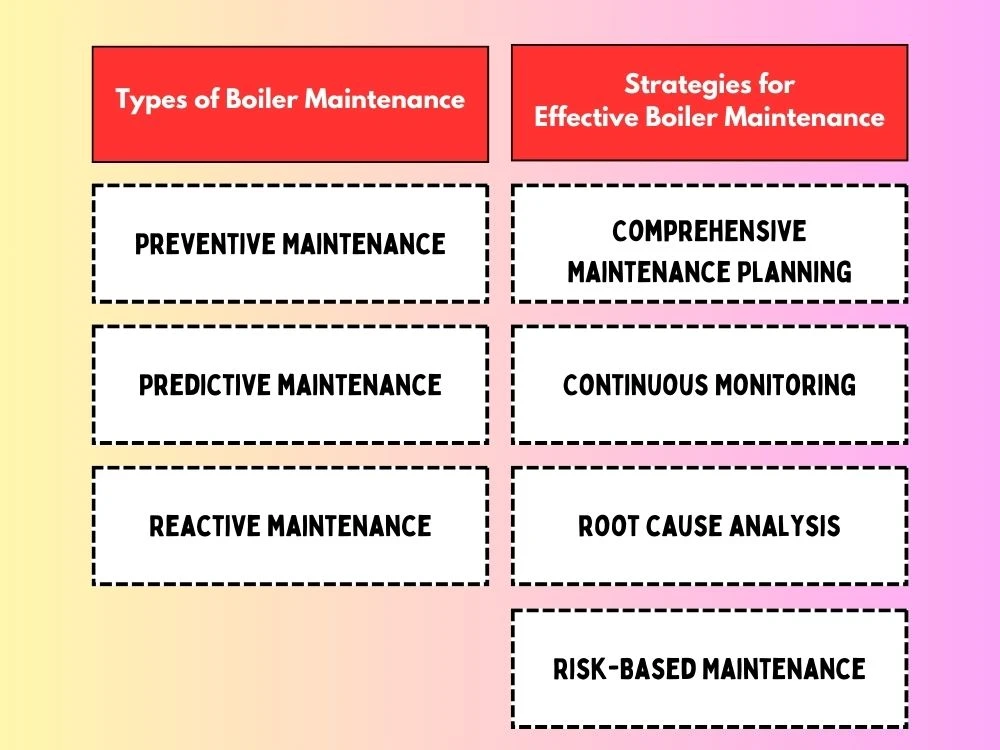

Industries approach several types of boiler maintenance to ensure operational continuity and safety. Here are some primary types of boiler maintenance:

1. Preventive Maintenance

As the name implies preventive maintenance is conducted before anything worse happens. To conduct preventive maintenance, a schedule is created which includes periodical maintenance activities like monthly, quarterly, bi-annually, and annually. Preventive maintenance includes:

- Inspect the boiler components regularly such as boiler tubes, safety valves, pressure gauges, fittings, etc.

- Clean all important boiler surfaces such as burner assemblies, firetubes, etc.

- Lubricate the parts like motors, pumps, etc.

- Test and calibrate the boiler controls and safety devices.

- Replace deteriorated components such as gaskets, seals, etc.

2. Predictive Maintenance

Predictive maintenance is based on historical data and patterns where maintenance requirements are predicted and conducted. Using proper data analytics techniques, industries can identify the probability of boiler equipment failure. This helps perform the maintenance part. Here are some examples of predictive maintenance activities:

- Monitor the operating parameters of the boiler equipment such as temperature, flow rates, and pressure in real-time.

- Analyze vibration to detect any abnormalities on rotating equipment like pumps, motors, and fans.

- Conduct thermographic tests to find out overheating in boiler components.

- Analyze boiler water chemistry via regular sampling and testing to avoid corrosion and scale buildup.

- Utilize essential predictive maintenance software systems to analyze historical data and predict potential equipment failures.

3. Reactive or Corrective Maintenance

As the name implies reactive maintenance is the process of doing boiler maintenance after a problem occurs. It is a remedial action to an issue. This type of maintenance is quickly done to make the operation return to normal condition as soon as possible. Here are some corrective maintenance examples:

- Immediately respond to the warnings and alarms in the boiler system.

- Conduct necessary emergency repairs on faulty boiler components.

- Remove debris that causes unnecessary blockages in the boiler system.

- Conduct a comprehensive investigation when a boiler malfunction occurs.

- Develop crucial contingency plans to minimize breakdowns in the system.

Strategies Employed by Industries for Effective Boiler Maintenance

Industries utilize several strategies to effectively conduct boiler maintenance. This is crucial to ensure continuous system operation. Some key strategies are known as:

- Comprehensive Maintenance Planning: To conduct crucial maintenance types like preventive, predictive, and reactive maintenance, a comprehensive maintenance plan effectively helps. It includes essential duties of responsible personnel, maintenance frequencies, and other important things.

- Continuous Monitoring: Industries use advanced software technologies like sensors, monitoring software, and data loggers to monitor boiler and its components continuously. This is important for effective boiler maintenance.

- Root Cause Analysis: Root cause analysis helps figure out primary and secondary reasons for boiler failures. Fishbone diagrams and fault-tree analysis are some examples of root cause analysis.

- Risk-Based Maintenance: It is vital to prioritize maintenance activities based on the risk parameters. Risk-based maintenance effectively helps allocate more resources and attention toward high-risk component maintenance.

Final Thoughts

The boiler is a critical piece of equipment in industries that needs proper attention and maintenance. Industries like healthcare, hotels, and manufacturing use boilers to fulfill their laundry, cooking, and sterilization purposes.

The boiler itself is a highly dangerous piece of equipment that tends to create more damage to the entire facility when it is not properly maintained. Therefore, industries provide proper attention to properly conduct maintenance activities such as preventive, predictive, and corrective maintenance.

A pressure converter tool is very useful for performing all crucial maintenance types where pressure buildup and reduction are serious issues in the boiler system. When conducting maintenance, technicians and engineers need to monitor the pressure levels continuously and this tool is efficient to convey measurements in various pressure units.

FAQ

Q1: Why is boiler maintenance important?

Boiler maintenance is important to ensure smooth boiler operation and safety. Maintenance failures can cause breakdowns and fatalities in industries.

Q2: How does the pressure converter help maintain boiler equipment?

Maintaining a standard pressure level is crucial in boiler maintenance and the pressure converter tool is useful to understand different pressure measurement units accurately.

Explore Related posts

https://smarttoolsai.com/post/why-efficient-building-management-system-is-crucial-for-your-business

https://smarttoolsai.com/post/food-and-beverage-industry-and-electric-unit-converters

.webp)