What Is Inventory Management? Definition, Benefits, and Key Techniques

Ever ordered something only to get that heartbreaking email “Sorry, your item is out of stock”? Honestly, it’s not just annoying, but it’s a major failure on the seller’s part. That’s exactly why inventory management matters so much.

Understanding the ins and outs of inventory management can help your business operations get a lot better. It's absolutely essential to know how to monitor and manage your inventory, whether you are the owner of a small retail shop or the manager of a big warehouse. Doing it right will mean more satisfied customers and increased profits.

Let's explore what inventory management actually is, why it's important, and what techniques help you maintain a balance with your stock.

Key Takeaways

- Learn what inventory management is and why it matters for your business success.

- Understand the core elements of inventory management like stock control, reorder point, safety stock, lead time, etc.

- Discover the benefits of managing inventory and eight proven techniques.

- Find out which modern tools can automate your inventory tracking.

- Explore the common mistakes that drain cash and frustrate customers. Plus, find solutions to avoid them.

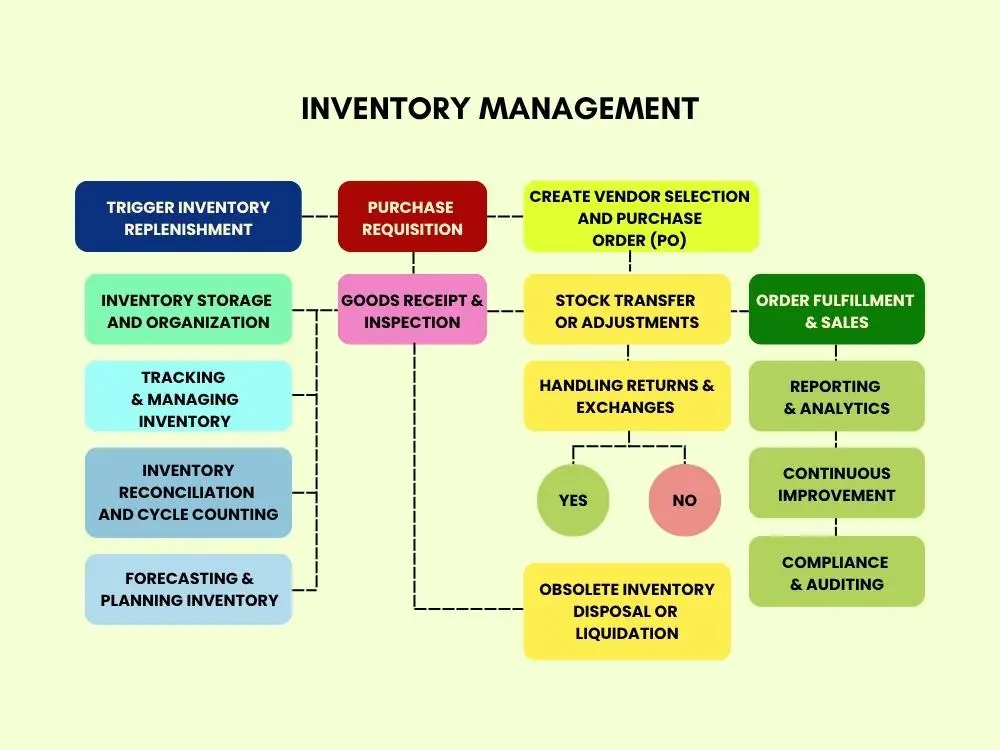

What Is Inventory Management?

It's the process of tracking, ordering, storing, and selling your inventory aka, all the stuff your business buys, makes, or sells. In simpler terms, it’s how you make sure you’ve got the right products, in the right amount, at the right time.

Inventory management involves handling a lot of moving parts. Supplier lead times, demand forecasting, reordering points, carrying costs, and the list goes on. If you’re not paying attention, your cash could get stuck in piles of unsold stock faster than you can say “warehouse clearance sale.”

Why Inventory Management Matters

It's a must for many reasons. Let us uncover the most significant ones:

- It Keeps Your Customers Happy: When placing an order, customers expect a quick delivery and no surprises at all. Good inventory management makes sure you always have what they want, at the right time.

- It Saves You Money: If you have too much stock, you’re basically holding money that could've been used elsewhere. On the other hand, if you have too little stock, you’re missing the sales opportunities. A smart inventory strategy pinpoints that sweet spot so your money is working for you and not against you.

- It Improves Efficiency: The whole process becomes faster when you know the exact location of every item. No more desperate, where is that box of widgets? situations.

- It Reduces Waste: Especially for businesses that deal with perishable or seasonal goods, inefficient tracking can lead to stock that is expired or obsolete. Good management gives fewer write-offs and less guilt.

Essentially, inventory management is what prevents your business from being a logistical nightmare.

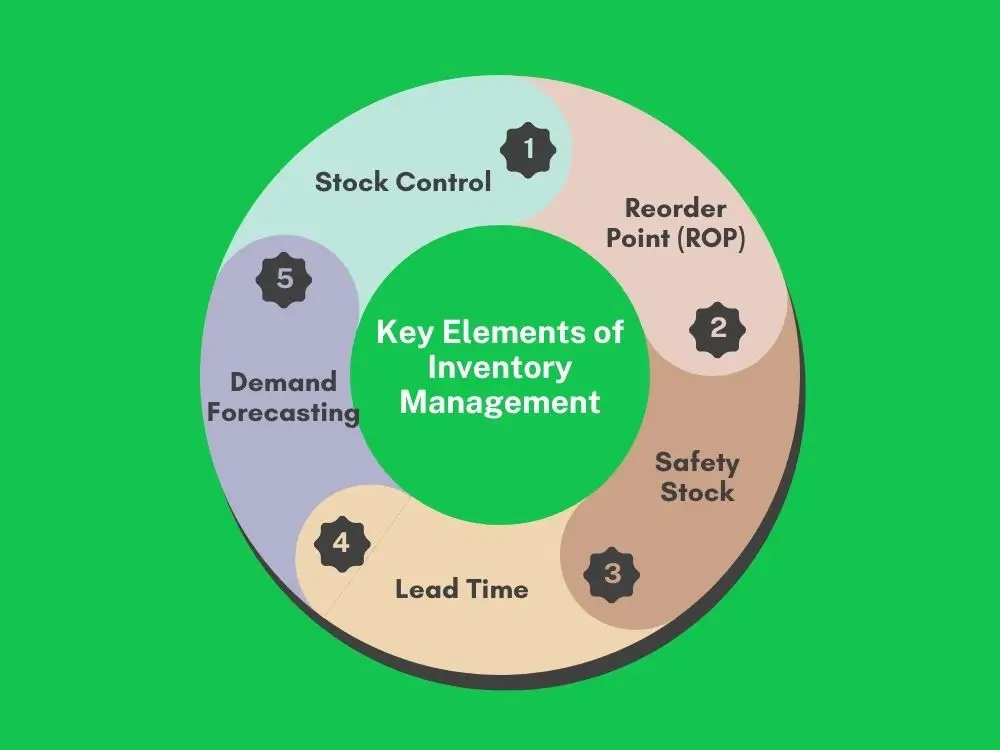

The Core Elements of Inventory Management

You can’t just wave a barcode scanner around and call it a day. Effective inventory management involves several interdependent components that must work together.

1. Stock Control

This is the bread and butter of inventory management. It’s about knowing:

- What you have

- Where it’s stored

- When you need more

Think of it like the “Google Maps” of your warehouse, which tells you what’s where and how to get it efficiently.

2. Reorder Point (ROP)

The ROP is the stock level that triggers a new purchase order. If you wait too long, you’ll face stockouts. When you order too early, you’ll clog up your shelves.

Pro tip: Utilize automation software to automate this calculation, eliminating the need for manual input.

3. Safety Stock

This is your just-in-case buffer, which helps you handle sudden spikes in demand or supplier delays without disappointing your customers.

4. Lead Time

Lead time is how long it takes for new stock to arrive after you order it. Understanding this helps you plan purchases strategically instead of panic-buying last minute.

5. Demand Forecasting

Ever wish you had a crystal ball for predicting sales? Demand forecasting is the next best thing. It uses historical data, market trends, seasonal patterns, and other vital aspects to estimate future demand.

Key Inventory Management Techniques

Now, coming to the important part, the actual methods you can use to manage your inventory like a pro.

| Technique | Description |

|---|---|

| 1. ABC Analysis | Ever heard of the Pareto Principle? The 80/20 rule? Well, it applies here too

By focusing more on your "A" items, you maximize profit and minimize wasted effort. |

| 2. Just-in-Time (JIT) Inventory | JIT means you order stock only when you need it. It saves space and reduces holding costs. But beware that JIT is like walking a tightrope. One supplier delay and you're toast. (Ask anyone who tried this during global shipping delays. |

| 3. FIFO (First-In, First-Out) | FIFO ensures you sell older stock before newer arrivals. This is mostly important for products with expiration dates (like food or cosmetics). Plus, it prevents dusty boxes from haunting your shelves forever. |

| 4. LIFO (Last-In, First-Out) | LIFO is the opposite that it sells the newest stock first. It's less common outside accounting circles but sometimes used in industries where costs fluctuate fast (like raw materials). |

| 5. Economic Order Quantity (EOQ) | EOQ helps you figure out the ideal order size that minimizes total costs. Ordering too much increases storage fees, while ordering too little lead to more frequent orders. The EOQ formula helps you balance both. |

| 6. Dropshipping | If you hate managing physical stock, dropshipping might be your jam. You sell the product, your supplier ships it. No warehouse, no stock headaches. But the downside is you have less control over delivery and product quality. But for low-risk entry into eCommerce, it's gold. |

| 7. Batch Tracking | Batch tracking aka lot tracking allows you to follow products through the production process until the moment they are sold. It's essential to facilitate traceability if you manufacture products in the food, health, or electronics space. |

| 8. Perpetual Inventory System | This system updates inventory records in real-time using software. It's like having a live heartbeat of your stock. Manual counting feels ancient once you switch. |

The Benefits of Good Inventory Management

Okay, now that we’ve defined it, let’s talk about the good stuff (the benefits) that make all that effort worthwhile.

- Better Cash Flow: Inventory is expensive. When you optimize your stock levels, you free up money to invest in other areas of your business like marketing, product development, hiring, or even that espresso machine you’ve been eyeing.

- Happier Customers: No one likes “out of stock” messages. When you manage inventory properly, it'll help enhance customers' trust, where they'll buy and recommend you more.

- Fewer Mistakes: Manual tracking has errors due to human involvement (ask me about the time I ordered 1,000 units instead of 100). This is also why we need to use automated tools to keep the data accurate and, more importantly, your stress levels down.

- Smarter Business Decisions: With solid inventory data, you can easily identify best-sellers. Plus, you can phase out underperformers and spot seasonal trends early. Basically, your reports start making sense instead of looking like abstract art.

Modern Inventory Management Tools

Nobody wants to track stock with a clipboard anymore. Companies these days use inventory management software to automate and simplify the process. Let's see a few highlighted tools to consider:

- Zoho Inventory: A well-rounded inventory solution for mid-sized or small businesses.

- Cin7: Integrates well with eCommerce platforms and POS systems.

- NetSuite ERP: A powerful option at a higher price point. Best suited for large-scale operations.

- InFlow Inventory: A great intuitive and easy solution for users new to inventory tracking.

These tools handle everything from barcode scanning to forecasting. They also generate analytics that help you plan better. And the best part is they reduce those “oops” moments that make you want to scream into a box of mislabeled merchandise.

Common Inventory Management Mistakes & How to Avoid Them

Now, let's see the common mistakes people make, which I’ve also made at some point. However, that's how we learn and identify common fixes for those errors.

- Overordering: You may think safe stock is better than saying sorry, but then your warehouse starts looking like a Costco overflow section. Avoid this by setting clear reorder points.

- Ignoring Data: Gut instinct is great. However, ignoring the data will create a problem every time. You will want to use an inventory report and sales data to help steer your decisions.

- Not Training Your Team: If your staff doesn’t get proper training to understand your system, they’ll mess it up. So invest in training, and it pays off fast.

- Skipping Audits: Even with automation, you still need to physically count stock sometimes. Auditing is a cost-effective way to catch problems early. Make a schedule for your regular audits.

- Poor Supplier Communication: Bad suppliers cause bad inventory. Keep open communication and diversify vendors when possible. Also, check this article for proper vendor management.

Tips to Level Up Your Inventory Game

Let’s wrap up the practical part with a few pro tips you can start using today:

- Automate everything you can, where manual tracking is so last decade.

- Use barcode scanning to speed up receiving or picking.

- Integrate your systems (POS, accounting, CRM) for real-time data flow.

- Review performance often and don’t wait until something breaks.

- Stay flexible. Market demand changes faster than you think.

Your inventory process should grow with your business instead of working against it.

Wrapping Up

Inventory management keeps your business from falling apart. It's really that simple. You don't need a costly system or perfect execution from day one. You just have to start tracking what really matters and fix problems as they pop up. This is essential to keep your customers happy and boost your profit.

FAQs

Q1: What are the 4 types of inventory?

Raw materials, work-in-progress, finished goods, and maintenance supplies are the main types. Most firms have to deal with at least two of those.

Q2: What is an example of inventory management?

A coffee shop tracking beans, cups, milk, and similar stuff. They reorder before running out, but don't buy so much that products expire.

Explore Related Posts

https://smarttoolsai.com/post/total-manufacturing-cost

https://smarttoolsai.com/post/time-converter-applications-in-global-operations

.webp)