What are Business Functions and Integrating a Weight Converter with Them

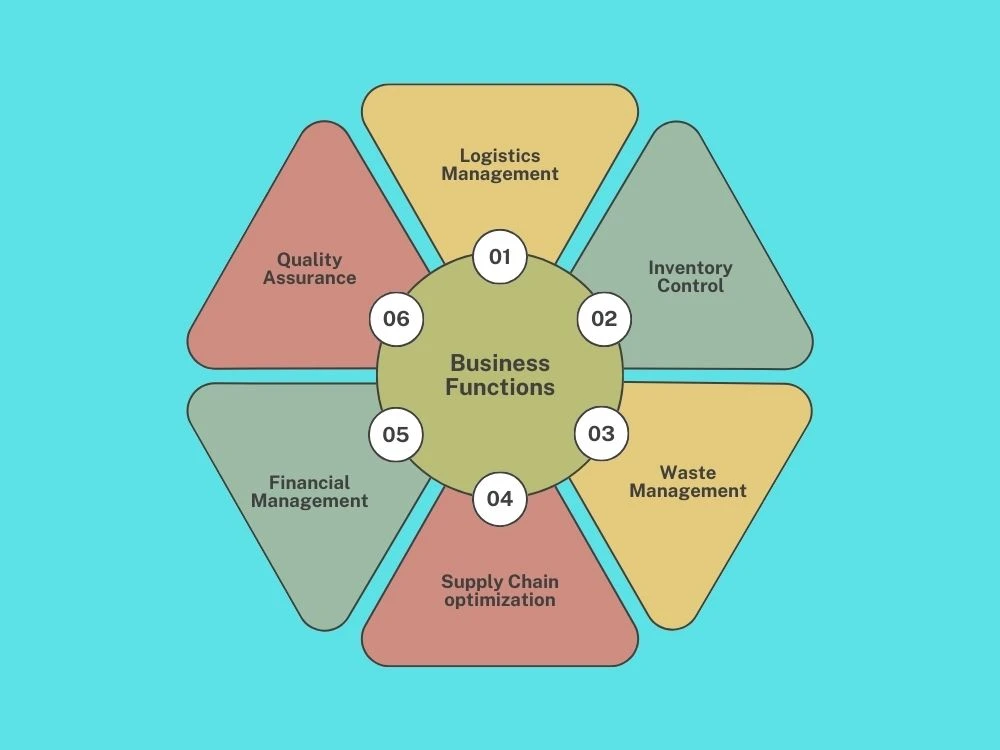

A business organization has to deal with several business functions. These functions are crucial for a continuous business operation. It’s like the lifeblood of a company. Managing the key business functions is essential where respective departments and employees are responsible.

According to the business or industry type, these functions vary. Generally, a business has common functions like inventory management, financial management, quality control, supply chain, logistics, and many others.

A weight converter is used to convert different weight units and is necessary when conducting different operations in an organization. In this article, we will discuss how a weight converter is integrated into various business functions.

Key Takeaways

- Understand and identify what are business functions.

- Learn, how a weight converter is integrated into key business functions.

- Understand the importance of integrating a weight converter with these functions.

Key Business Functions and the Integration of a Weight Converter

01 Logistics Management

Logistics management is an essential function in many companies. It involves the process of planning and controlling the movement of products. A company’s products reach the customers with proper logistics management in place.

It involves transportation, proper inventory and warehouse management, and order fulfillment. A weight converter is integrated with logistics management in the following areas:

- Accurate Shipping Calculations: Since logistics involves shipping, a precise weight measurement is crucial for accurate shipping calculation. Here the weight converter is helpful in accurately measuring the shipping costs of goods.

- Packaging optimization: Correct packaging is vital to reduce shipping costs. Here the weight converter is useful to choose the right packaging material and size for the specific product. Based on the product weight, the packaging size and material are selected. The weight converter helps identify different weight units accurately for choosing the right packaging.

- Streamlining Shipment Process: A weight converter integration helps streamline the shipment process in logistics management. It reduces unnecessary processing time and leads to a quicker shipment to the customers.

Example: A company uses pound mass (LBM) as the standard weighing unit for their products. The shipping company charges $8 per Kg. Here, the company wants to identify the accurate shipping cost for a collection of products weighing 1500 LBM:

- Shipping company charge = $8 per Kg

- Shipping products' total weight (1500 LBM) equals in Kilograms = 680.39 Kilograms

- So, the shipping cost equals to = 680.39 Kg * $8 = $5443.12

02 Inventory Control

Inventory control is a systematic approach to managing the stock of a company’s goods and materials. It includes monitoring the inventory in and out and ensuring proper stock level and a fair amount of resource utilization.

Effective inventory control is necessary to match customer demand, reduce inventory holding costs, and increase profitability. A weight converter is useful for performing proper inventory control in the following ways:

- Track Inventory Levels: This is a crucial function where tracking inventory levels helps maintain the stock. This can also reduce excessive or insufficient inventory stocks. Here the weight converter is used to measure the inventories and their weights to match them with the storage capacity.

- Optimize Replenishment: Using the weight data, it will be easy to determine when to reorder. This can also assist in timely replenishments and prevent stock shortages.

- Determine Storage Capacity: According to the weight of inventory items, the company can determine the storage capacity. It helps plan the inventory purchases or productions based on the warehouse storage capacity.

Example: A supermarket firm has a warehouse storage capacity of 3 tons. The storage has been quarterly (25%) filled with grocery stuff. They want to procure some essential grocery products to refill the storage up to 90%. Here the remaining 65% equals:

- Filled storage area – 3 tons * 25% = 0.75 Tons

- Refilling storage area – 3 tons * 65% = 1.95 Tons

The supermarket buys products in kg units. So, they use the weight converter to measure the kilograms amount respective to tons which equals 1950 kg.

03 Waste management

Waste management is a significant business function that ensures a hygienic pleasant working environment. Every day, a huge amount of waste is generated on business premises, and managing them is a mandatory task.

Managing waste involves a sequence of processes like segregating, storing, transporting, and disposing. A weight converter is useful for quantifying the generated waste and is essential in certain conditions.

For example: A company segregates its waste into different categories like food waste, polythene, discarded papers, and sharps. The segregated wastes are stored inside the business premises temporarily until the collection crew picks them up. When storing, the company weighs the waste for certain reasons like cost calculations.

They use Kg as the standard measurement unit and the collection crew charges for pounds. Last month the company generated approximately 350 kg of food waste which the collection crew charges $1.5 for a pound. Here the company used the weight converter to identify the cost:

- 350 Kg equals 771.62 Pounds

- So, the cost for collection is 771.62 * $1.5 = $1157.43

04. Supply Chain Optimization

Supply chain optimization involves all necessary matters related to the supply chain network. Some primary functions are identified under the supply chain like procurement, inventory management, warehousing, dispatching, and production.

A business should integrate a weight converter tool to fulfill these functions effectively, Key aspects of supply chain management include:

- Forecasting the Customer Demand: It is crucial to forecast the customer demand which helps ensure the availability of products in the business. Here a weight converter is helpful to maintain adequate stock level to match the customer demand.

- Vendor Relationship Management: Maintaining a good relationship with the vendors or suppliers is essential. When procuring materials from the vendors, the weight converter is used to identify different weight units accurately. This helps ensure proper procurement, pricing, and vendor relationships.

- Production Planning: Integrating a weight converter is useful for planning production effectively. It helps calculate different weight measurements accurately when producing goods.

Example: A snack production company manufactures 1500 units of snack packets every day. To produce this amount, they source materials from the vendors. Here are the details related to the production:

- Monthly Production = 1500 units * 25 operating days = 37500 snack packets

- One snack packet weight = 50 grams

- Materials purchased for production (flour, salt, etc.) = 150 kg

- Materials cost = $1500 ($10 per kg)

Here, the weight converter is used to convert between weight units to accurately plan the production and calculate the cost. It will help set accurate pricing for the snack.

- Material cost per 50g production = 50g equals 0.05kg

- = 0.05 kg * $10

- = $0.5 per packet

Assuming other operating expenses for producing one snack packet as $0.25

So, the production cost equals $0.75 for a snack packet. Assuming that the company adds a 50% profit margin and the final price is: $0.75 + $0.375 = $1.125

The weight converter quickly converts grams to kilograms which will help calculate single snack packet production cost. Using this calculation, the company can set its product price.

05. Financial Management

Financial management involves all kinds of finance-related planning, organizing, and controlling. In a business firm, there are different sections where the finance division has a connection with every department to ensure continuous operation.

Marketing, procurement, production, administration, and other related divisions need adequate finance to run. Here, a weight converter helps properly plan finance-related stuff in different sections.

Example: A jewelry business needed to purchase some 500 grams of gemstones for jewelry production. To calculate the accurate budget for the gemstones, the procurement department required correct weight measurements in carat.

Here they used the weight converter to convert grams to carat. One gram equals 5 carats and the purchase of 500 grams of gemstones equals 2500 carats. This quick conversion helps make financial decisions where the carat is the standard unit for selling jewelry.

06. Quality Assurance

Ensuring the quality of the products is one of the prominent business functions. The standard weight is somehow viewed as one of the quality aspects. A weight converter helps determine the quality of the products by fixing the right weight.

Example: A food manufacturing company utilizes the weight converter to ensure the quality of their products. They offer food packs of the right weight to fulfill the customers’ needs. Some customers request different quantities in different weight scales such as grams, kilograms, and ounces. Based on the customer requirements the company offers food packs and they use a weight converter to assess the right weight.

Wrapping Up

Every business has different business functions based on its business type. These functions are crucial for continuous business operations. Integrating a weight converter is helpful in different ways to perform these functions such as logistics management, inventory control, waste management, supply chain optimization, financial management, quality assurance, and many more.

FAQs

Q1: What are business functions?

Business functions are essential activities that help run the business. It can be anything related to finance, production, logistics, or any other.

Q2: How does a weight converter tool help perform business functions?

A weight converter tool assists in performing various business functions by accurately converting different weight units. This is crucial to performing functions like logistics management, inventory control, quality assurance, waste management, and many others.

Q3: How many Pounds (LBM) equals a kg?

A kg equals 2.2 pounds (LBM). If a big product weight is 100 kg that equals 220.46 pounds.

Q4: How many ounces mass (OZM) equals a kg?

One kg equals 35.27 ounces. It means a 10 kg product equals approximately 353 ounces.

Explore Related Posts

https://smarttoolsai.com/post/food-and-beverage-industry-and-electric-unit-converters

https://smarttoolsai.com/post/temperature-converter-in-food-manufacturing-hvac-system-and-laboratory

.webp)