What Is Procurement Management? Definition, Process, and Best Practices

Some companies always get the best deals and top-tier suppliers, while others constantly scramble or blame supply chain issues for literally everything. The difference usually comes down to one thing, which is effective procurement management.

As someone who's dealt with suppliers who ghost, shipments that vanish into the abyss, and discounts that were definitely not discounts, I can promise you that mastering procurement management can save you money and stop you from pulling your hair out every time an order goes sideways.

Key Takeaways

- Understand what procurement management is and why it matters.

- Learn the step-by-step procurement process that keeps businesses running smoothly.

- Discover best practices that save money and build stronger supplier relationships.

- Explore modern procurement tools worth considering.

- Avoid common procurement mistakes that waste time and drain budgets.

What Is Procurement Management?

Procurement management is what we call the integrated approach to sourcing, selecting, negotiating, and buying products or services that are needed to keep the company going. Simply, you first identify your needs, then search for a provider, negotiate the price, and finally ensure the delivery at the agreed time.

Procurement isn't just buying stuff. It also includes:

- Evaluating vendors: Checking if suppliers are reliable and worth your money.

- Negotiating contracts: Getting better prices and terms that work for you.

- Managing supplier relationships: Keeping suppliers happy so they prioritize your orders.

- Tracking spending and performance: Monitoring where money goes and supplier quality.

- Reducing risks and fraud: Preventing scams, delays, unauthorized purchases, and other risks.

If inventory management is about controlling what’s already on your shelves, procurement management is about getting those items there in the first place.

Why Procurement Management Actually Matters

While procurement is an overlooked area of the organization, your Finance team would tell you that it's never boring. Poor procurement practices will deplete budgets faster than you can say “unapproved vendor markup.” But good procurement management has multiple advantages, such as:

- Saving Cost: A competent procurement team will get better negotiated contracts and avoid waste, which mitigates overspending. Better procurement equals more profit. It is basic math.

- Supplier Relationships: When you treat your suppliers like partners instead of a vending machine, you can expect improvements in the quote lead-time, greater price flexibility, a willingness to move you to the front of the line when supply threatens to run short, etc.

- Lower Risk: Good procurement adds accountability and compliance that will help you to avoid unpleasant surprises (Ex, you don't pay for stuff that just never shows up).

- Reliability of Quality: A proper procurement process ensures you don’t get stuck with cheap knockoffs or unreliable services.

- Operational Communication: A simplified process provides some assurance that the rest of the organization runs smoothly. No excessive delays, nothing to respond to or clean up without unnecessary chaos.

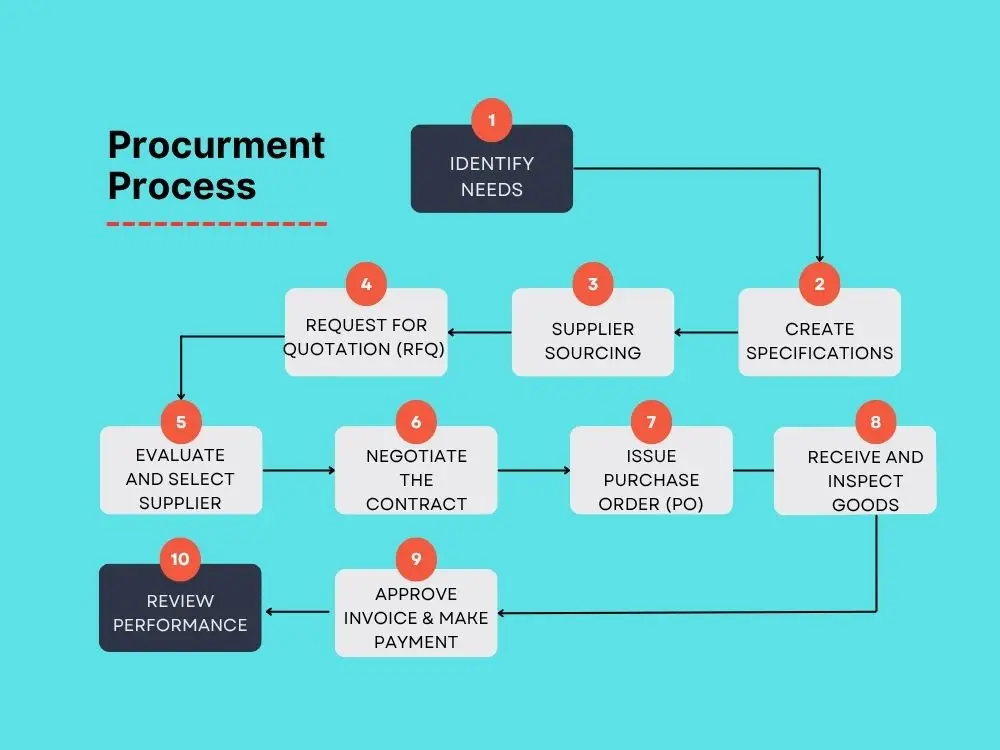

The Procurement Management Process (Step-by-Step)

Now, let’s discuss how procurement operates. A lot of companies follow a similar process, even if they call the steps by different names.

1. Identify Needs

Someone in the company needs something like raw materials, equipment, software, a contractor, etc. Procurement begins when the need is clearly defined.

2. Create Specifications

You outline exactly what you want:

- Quantity

- Quality

- Timeline

- Budget

- Requirements

This is where clarity saves future headaches.

3. Supplier Sourcing

You search for potential suppliers. This might mean:

- Browsing supplier databases

- Attending trade shows

- Checking referrals

- Reviewing existing vendor lists

4. Request for Quotation (RFQ) or Proposal (RFP)

For bigger purchases, send out formal requests for proposals or quotes. This gives you standardized information to compare suppliers fairly. Also, be clear about your requirements.

5. Evaluate and Select Supplier

You choose the best supplier based on:

- Price

- Quality

- Reliability

- Reputation

- Delivery speed

- Contract terms

IMO, gut instinct still matters. If a supplier gives you bad vibes, trust your radar.

6. Negotiate the Contract

You should negotiate the following in this step:

- Cost

- Delivery terms

- Payment terms

- Penalties

- Warranties

- Support

7. Issue Purchase Order (PO)

The PO makes the buying decision official and trackable. This is your legal protection and ensures everyone's on the same page about what's being purchased.

8. Receive and Inspect Goods

When the delivery arrives, you inspect it. Does it match the PO? Is it damaged? Missing? Wrong color? Wrong everything? Now’s the time to call it out.

9. Approve Invoice and Make Payment

Once everything checks out, finance pays the supplier. Consider timely payment, which builds good supplier relationships and sometimes qualifies you for early payment discounts.

10. Review Performance

Great procurement teams don’t stop at payment. They review:

- Was the supplier reliable?

- Was quality consistent?

- Was the price fair?

Poor performers get replaced. High performers get more business. Also, check this guide to know more about performance management systems for small businesses.

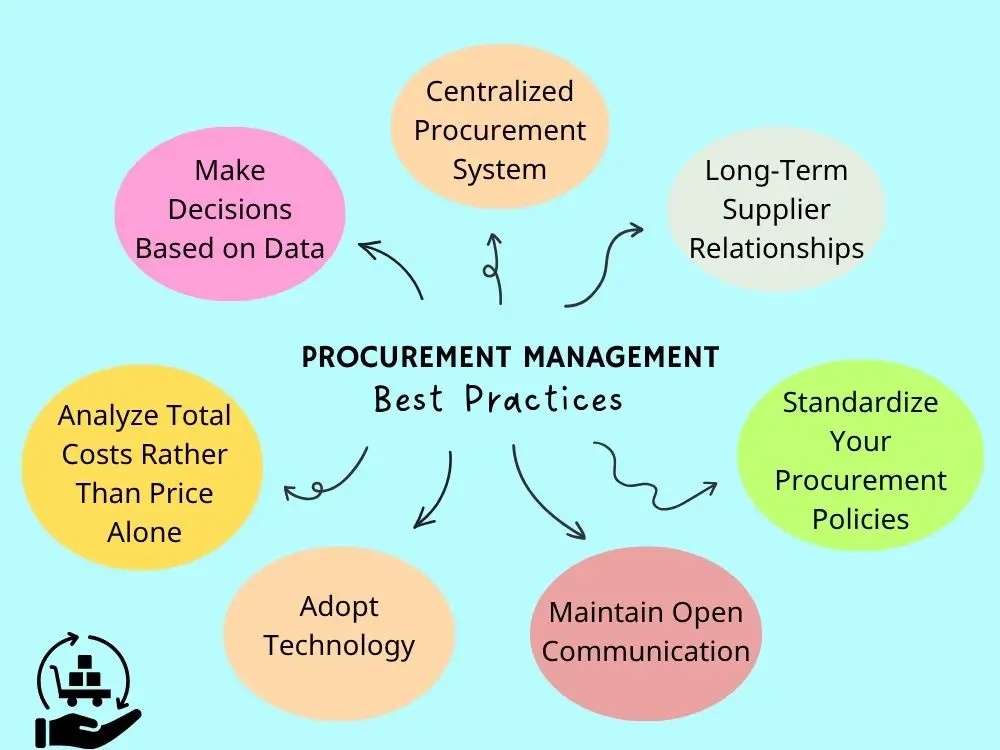

Best Practices for Procurement Management

You now know the process. But what separates a normal procurement process from an amazing one? These are the best practices.

- Centralized Procurement System: Use a particular procurement system or a platform. This helps minimize scattered emails or random spreadsheets.

- Long-Term Supplier Relationships: A good relationship with the supplier will enable you to get the supplies without delay, even if the demand increases suddenly.

- Make Decisions Based on Data: Data is important, and it helps track lead times, supplier performance, total cost of ownership (TCO), and year-over-year savings. It empowers better decisions.

- Analyze Total Costs Rather Than Price Alone: You must analyze everything without only looking at price. Maybe a supplier offers a very low cost, but you may incur the most expensive delays or hidden fees from them sometimes. This is why you need to always examine total costs.

- Standardize Your Procurement Policies: Establish rules for vendor approval, spending limit, contract length, and documentation. This helps combat fraud and bias in vendor selection.

- Adopt Technology: The use of procurement software will allow you to streamline the process, encompassing getting approvals, PO issuance, invoice processing, supplier tracking, and other operations. The best part is that automation diminishes human errors and headaches to a large extent.

- Maintain Open Communication: Effective communication is the key that opens the door to proper dealings with all parties involved, such as suppliers, contractors, finance, and others. Otherwise, one little thing can cause the downfall of the whole process.

Modern Procurement Tools Worth Considering

Technology simplifies everything. It makes procurement faster and more accurate. Let’s see some of the tools that organizations use:

- SAP Ariba: A well-rounded procurement platform for big organizations. It supports sourcing, contracts, and supplier management.

- Coupa: A cloud-based procurement software that is easy to use and scalable. Good for mid to large-sized organizations.

- Procurify: For small and mid-sized organizations. Very easy to use, and you won't need a PhD to set this up.

- Kissflow Procurement Cloud: A less expensive tool that has solid functionality for firms that need to professionalize their procurement.

- Zip (formerly Zip HQ): A robust option for managing intake and approval workflows. Good tool to make procurement requests less chaotic.

The tools will help you manage and streamline the purchasing process from purchase requisitions to purchase orders to managing suppliers to spending analytics. Each of these tools also significantly eases the audit process when tax time approaches.

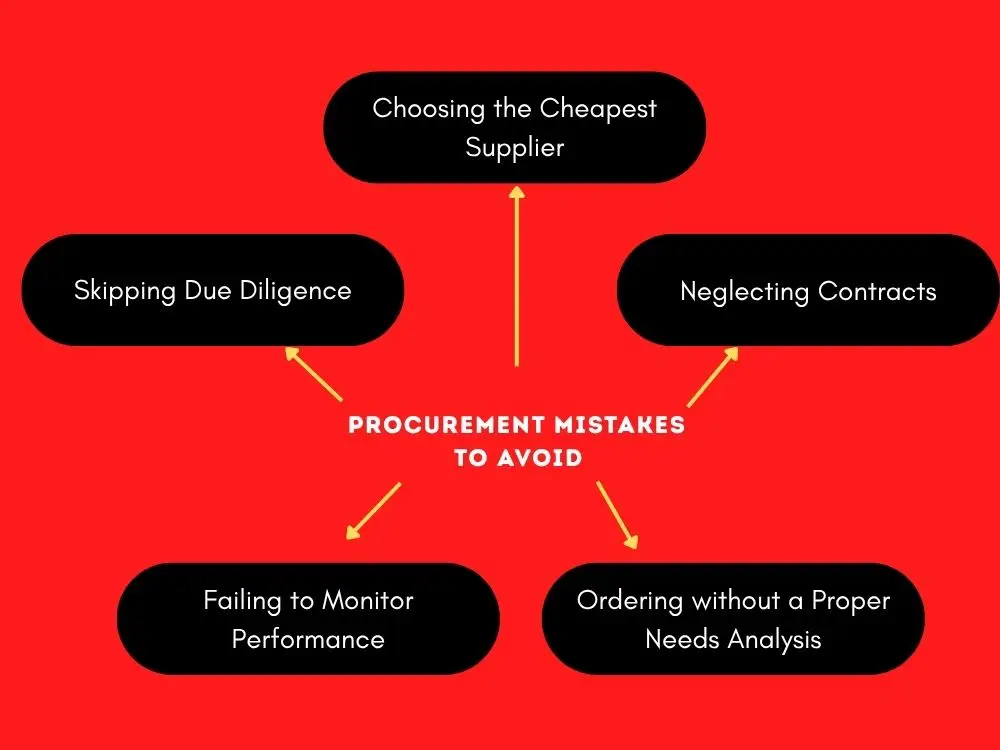

Common Procurement Mistakes to Avoid

You have to know and avoid these common procurement mistakes to save yourself from pain:

- Choosing the Cheapest Supplier: It's a mistake to always select the lowest price. Instead of a price choice, consider other relevant things such as delivery time, shipping, installation, maintenance, quality, etc.

- Skipping Due Diligence: Avoiding proper due diligence on suppliers is a costly mistake. It can lead to unwanted surprises. So, do reference checks, assess the financials, and prior performance of suppliers before finalizing your purchase decision.

- Neglecting Contracts: Contract terms matter. Look thoroughly at the contract terms and ensure they are in your favor, especially relative to the quality, delivery timeliness, resolution, product performance, and warranty.

- Failing to Monitor Performance: Don't stop monitoring the performance of your suppliers or the procurement process.

- Ordering without a Proper Needs Analysis: It’s a waste when you order without a proper needs analysis. First, understand the requirements correctly before ordering.

Wrapping Up

Procurement management sounds boring until you realize how much money bad procurement is costing you. This guide helps you understand the process, tools, mistakes, and solutions in a nutshell. Start building better supplier relationships and stop rushing every order. Small improvements add up quickly than you'd think.

FAQs

Q1: What's the difference between procurement and purchasing?

Purchasing is simply buying something. But procurement is a broad area that includes the whole strategic process of planning, sourcing, negotiating, and managing the supplier relationship.

Q2: How long does the procurement process take?

It depends. It could take a few days if you buy something simple. However, a complex contract with a new supplier could take months. If done properly, you shouldn't find yourself rushing to purchase.

Q3: Do small businesses need formal procurement management?

Even a small business should work towards basic procurement practices. You may not need an enterprise-level software. But some strong processes and vetted suppliers will make you money and avoid problems.

Q4: How can I reduce procurement costs?

You can cut your expenses by negotiating better, pooling orders to cut the number of suppliers, planning ahead of time to avoid rush orders, maintaining strong connections with suppliers, and constantly reviewing spending for possible savings.

.webp)