What Is Quality Control? Methods, Tools, Process, and Best Practices

Quality control is more than just a checkbox on your clipboard. If you're in manufacturing, you probably already know the harsh reality. When quality drops, everything falls apart. Customers complain, scrap piles up, machines sit idle, and management scrambles for answers. So what's quality control, and how do you master it before the next batch goes sideways?

I learned to love QC after watching a production line churn out a mountain of expensive defects. It was a costly lesson I never wanted to repeat. Quality control is about having control and confidence that offers results. Let's understand it together so you can implement these practices and see real improvements in your operations.

Key Takeaways

- Understand what quality control is and learn the difference between QC and QA to use both effectively.

- Discover proven QC methods like SPC, control charts, root cause analysis, and more.

- Explore essential tools and free converters that make measurements accurate and consistent.

- Follow the complete quality control process from planning inspections to tracking improvements.

- Avoid common QC mistakes that lead to scrap, rework, and unhappy customers.

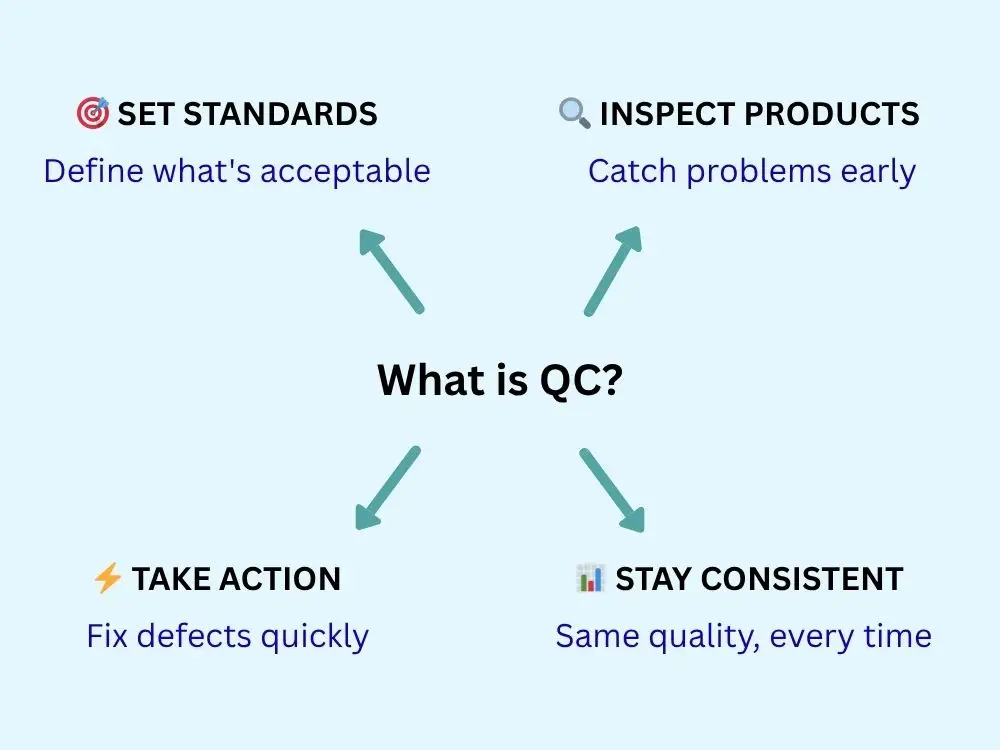

What Is Quality Control?

Quality control (QC) is a process of checking products or services to ensure they meet the standards before being delivered to customers. It's like a defense against defects and unhappy customers.

Here's how it works simply. You establish acceptable standards for what is good and what isn't good. You check your products and identify problems as they arise. If you find a defective product, you address it quickly and keep the good products moving.

QC isn't about being perfect every time, but being consistent. It protects your brand and minimizes waste while ensuring the entire organization runs the way it should.

Why Quality Control Matters

So, why should we even care about quality control if the machines appear to be running fine? Simple, when things go wrong, it gets really expensive in a hurry.

Quality Control allows you to efficiently reduce scrap and rework, consistently meet customer expectations, reduce production costs, improve cycle time, increase customer satisfaction, and safeguard your brand. You are investing in QC now so that you don't pay for the chaos later. This is the greatest trade-off in manufacturing.

Quality Control vs Quality Assurance

Some people misunderstand and think that both QA and QC are the same. However, they have clear differences. The following table discusses them well:

| Quality Control (QC) | Quality Assurance (QA) |

|---|---|

| Happens during or after production | Happens before production starts |

| Focuses on finding defects | Focuses on preventing defects |

| Reactive approach | Proactive approach |

| Inspects the final product | Improves the process itself |

| Example: Testing finished parts for size | Example: Setting up proper machine calibration |

| Responds with: "Is this product good?" | Responds with: "Is our process good?" |

| Done by inspectors and testers | Done by process engineers and managers |

Key Methods of Quality Control

Let’s talk about the key QC methods that actually work on the factory floor. No fluff. No theory for theory’s sake.

1. Statistical Process Control (SPC)

SPC uses real data to monitor whether your process stays stable. You take measurements to plot them and check whether the process behaves or drifts like a toddler in a toy store.

Why SPC works:

- It helps detect problems early.

- It reduces guesswork.

- It reveals trends and variation.

- It keeps your processes predictable.

- If you want reliable output, you need SPC in your toolbox.

2. Control Charts

Control charts help you visualize variation and determine when to intervene. You collect data over time and then compare it to upper and lower control limits. If a point is plotted outside control limits, you act relevantly.

Common control charts:

- X-bar and R charts

- p-charts

- c-charts

Control charts answer the real question: Is the process stable or spiraling out of control?

3. Acceptance Sampling

Sometimes you can’t inspect every unit. So you test a sample and decide if the batch meets your standards. It saves time and money as long as your sampling plan makes sense. This works well for large production where full inspection isn't practical.

4. Inspection

Inspection is the most straightforward QC method. You physically examine products at different stages of production to catch defects before they move forward. This can be visual checks or functional tests.

Some companies inspect at receiving, during production, and before shipping. It's simple but effective when done consistently.

5. Root Cause Analysis (RCA)

Have you ever fixed a problem only to see it come back a week later? RCA helps you prevent that. It digs deeper to understand the root causes of why the defect happened in the first place, not just what happened. The process may take more time upfront, but it saves you from fighting the same problem over and over.

Essential Tools for Quality Control

Great QC teams use great tools. Here are the classics that always earn their place on the floor.

The Seven QC Tools

These tools solve most factory-level quality problems when used well:

| Tool | What It Does |

|---|---|

| Check Sheets | Collects data in a structured way for easy analysis |

| Ishikawa (Fishbone) Diagrams | Identifies root causes by mapping potential factors |

| Histograms | Shows the distribution of data to spot patterns |

| Pareto Charts | Highlights the biggest problems worth solving first |

| Control Charts | Monitors process stability over time |

| Scatter Diagrams | Reveals relationships between two variables |

| Flowcharts | Maps out processes to find bottlenecks and errors |

These tools work because they simply make problems visible fast. You can fix issues faster when you can see them clearly.

Measurement and Inspection Tools

Your QC is only as good as your measurements. Here are the tools that keep your data accurate:

| Tool | What It Measures |

|---|---|

| Calipers and Micrometers | Precise dimensions down to thousandths of an inch |

| CMM Machines | Complex 3D measurements for tight tolerances |

| Go/No-Go Gauges | Quick pass/fail checks on the production line |

| Vision Inspection Systems | Automated defect detection using cameras |

| Surface Analyzers | Surface finish and texture quality |

| Digital Torque Tools | Fastening force to ensure proper assembly |

Your measurement system should be reliable. Otherwise, your data will mislead you. Ensure that you buy good tools and calibrate them frequently.

If you need a quick conversion, check out our free unit converters that include length, weight, temperature, pressure, torque, and more to avoid measurement errors when moving between systems.

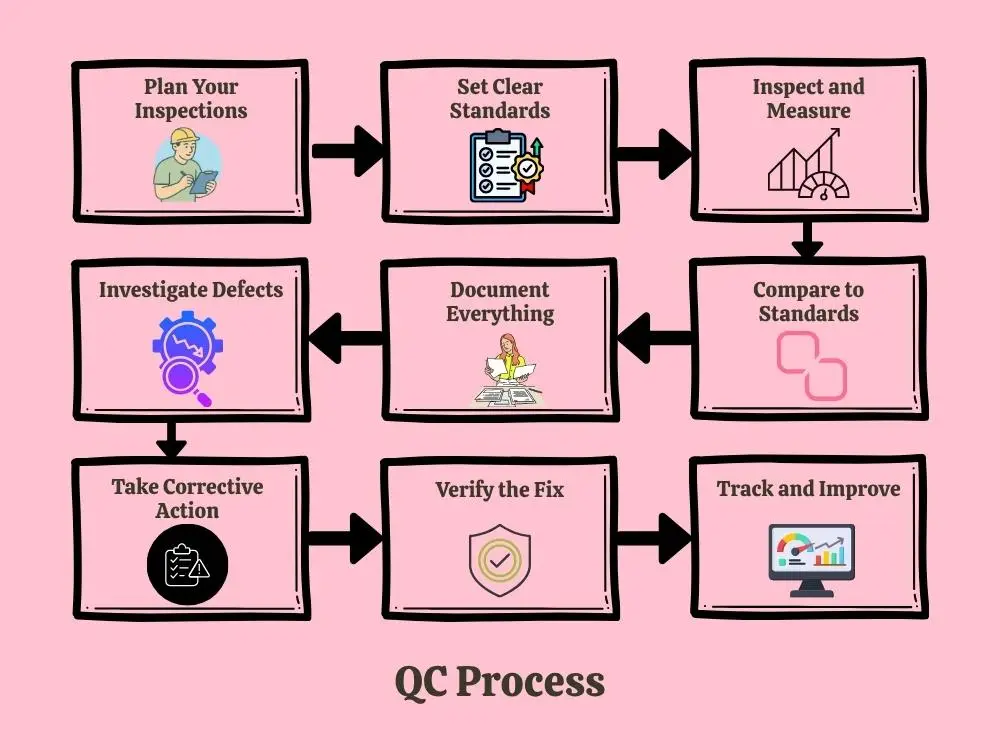

Quality Control Process

A good QC process is important to eliminate the possibility of defects getting through unnoticed. Here are the steps that occur in practice:

- Plan Your Inspections: Decide what to inspect and how often. Determine the critical control points of your production line.

- Set Clear Standards: Give specifications and acceptance criteria. Be very clear about what passes and what fails.

- Inspect and Measure: Inspect the product at the main locations, such as incoming materials, production and before shipping. Collect data using measuring tools.

- Compare to Standards: Compare your results with the criteria you set. Highlight anything that is outside of acceptable limits.

- Document Everything: Make a record of both passing and failing items. This information will be highly useful later on. Check the document control guide for more clarity.

- Investigate Defects: Investigate and take the defects down to their roots. Discover the cause of the problem.

- Take Corrective Action: Fix the issue and implement changes in the process. This helps avoid problem recurrence.

- Verify the Fix: Ensure that the changes you made actually worked.

- Track and Improve: Monitor the trends in quality over time and use data to improve the process.

Best Practices for Quality Control

Want a QC system that actually delivers? Follow these best practices.

- Train Your Team Properly: Invest in your inspectors. Skilled people catch defects quickly that untrained eyes miss. Certify them and keep their work skills updated with frequent refresher training.

- Audit Your Process Regularly: Audits might feel like a burden. However, they help catch process drift before it becomes expensive. Regular audits are good for eradicating problems early.

- Calibrate Your Equipment: Your measurements are good when you use better tools. Calibrate gauges and instruments on schedule. A drifting micrometer gives you bad data without warning.

- Work With Your Suppliers: Quality starts before materials hit your dock. Set clear expectations with suppliers and inspect incoming materials. A bad batch at receiving saves you from a disaster on the floor.

- Build a Culture of Improvement: Ask your team to spot problems and suggest solutions. The people running the machines often see issues before management does. Listen to them.

Common QC Mistakes and Solutions

Even experienced teams make these mistakes. Here's how to avoid them.

A) Mistake: No established quality standards

Solution: Make sure to write your standards in a place everyone can see. A spec sheet taped to the machine is better than hoping everyone will remember your tolerance.

B) Mistake: Skipping quality checks to save time

Solution: Don't skip your inspection checkpoints. They aren't optional, and a quick in-process inspection saves time sorting through piles of scrap later.

C) Mistake: Believing that QC is someone else's job

Solution: Create a culture where everyone owns quality without just the inspectors. Plus, reward teams that prevent defects more than just catching them.

D) Mistake: Not recognizing measurement errors

Solution: Run gage R&Rs and actively calibrate your devices regularly. Have the operators be educated so that they measure the same part the same way each time.

E) Mistake: Fixing symptoms instead of root causes

Solution: Use the tools you have such as either 5 Whys or Fishbone Diagrams. Dig as deep as you can until you potentially get to the real problem, then fix that root cause.

Wrapping Up

Quality control is a vital process that requires discipline. You need to set clear standards and measure consistently to fix problems at their source. The tools and techniques discussed in this guide only work if you apply them. Start small and maintain consistency, and you will notice your defects decline. Your customers will see the difference before you do.

FAQs

Q1: How much does quality control cost?

QC costs range depending on your operation size and complexity. You will want to budget for inspection equipment, training, software, and personnel dedicated to inspection. However, the cost associated with poor quality is much higher through scrap, rework, or potentially losing a customer.

Q2: What quality control certifications are valued in the industry?

Some common certifications are valued in industries like as ISO 9001 for quality management systems (QMS), Six Sigma for process improvement, and ASQ certifications for quality practitioners. They show your engagement in maintaining high quality.

.webp)